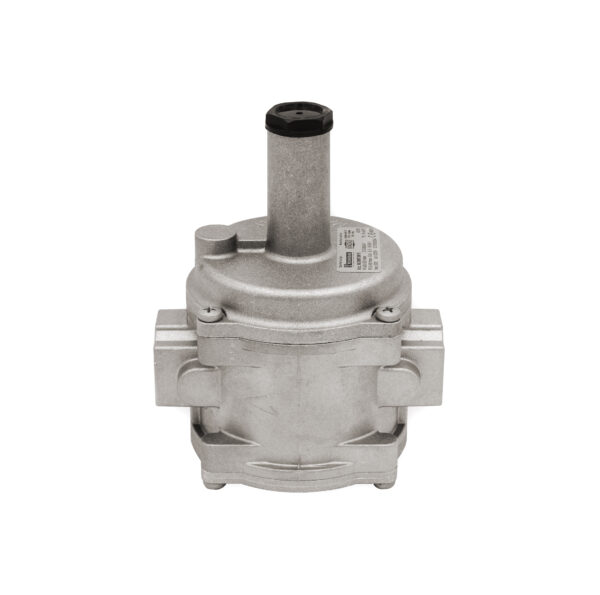

Double Membrane Stabilizer without Filter

RG/2MT model, maximum pressure 500 mbar

COMPLIANT WITH REGULATION (EU) 2016/426

| sku | model | price | info | add to cart | |

|---|---|---|---|---|---|

|

|

00000040139 |

DOUBLE MEMBRANE STABILIZER RG/2MT MODEL - 1/2" FF connections |

€51,15 Excl. Taxes |

Physical data UM Base: Dimension: Volume: Weight: Minimum Order Quantity: Customs data Customs Code |

Info Request |

|

|

00000040140 |

DOUBLE MEMBRANE STABILIZER RG/2MT MODEL - 3/4" FF connections |

€51,15 Excl. Taxes |

Physical data UM Base: Dimension: Volume: Weight: Minimum Order Quantity: Customs data Customs Code |

Info Request |

|

|

00000040141 |

DOUBLE MEMBRANE STABILIZER RG/2MT MODEL - 1" FF connections |

€51,15 Excl. Taxes |

Physical data UM Base: Dimension: Volume: Weight: Minimum Order Quantity: Customs data Customs Code |

Info Request |

Product informations

Device which supplies a preset and constant “downstream” pressure value, when the inlet pressure and/or the flow rate changes.

Equipped with

- spring for adjusting the output pressure

- safety membrane

- output pressure tap for controlling the output pressure

Technical Features

| USE | not aggressive gases of the three families (manufactured / natural / LPG) |

|---|---|

| INLET PRESSURE RANGE | 400 ÷ 500 mbar |

| OUTPUT PRESSURE RANGE | 16 to 60 mbar |

| INLET CONNECTION |

|

| OUTPUT CONNECTION |

|

| PRESSURE TAP | according to UNI 8979 |

| OPERATING PRESSURE | - 15°C ÷ + 60°C |

| MATERIAL | die-cast aluminum |

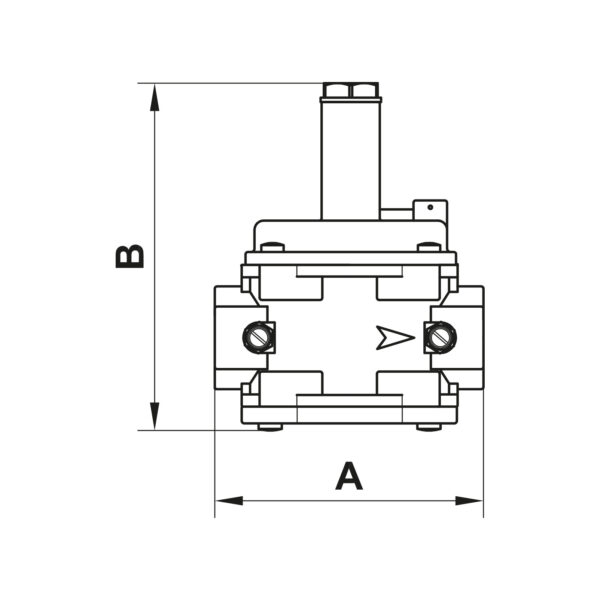

| DIMENSIONS | 120 x 152 mm (AxB) |

INSTALLATION: the regulator is normally placed before the utility and should be installed with the arrow pointing towards the utility, installation in a horizontal position is recommended. A pressure tap is placed outside the regulator and downstream of it for control of the regulating pressure.

SETTING: Before starting the system, make sure that the spring provided with the regulator is adequate for the desired regulating pressure. After removing the cap, place the regulator at the minimum setting (fully unscrewed), then start the system and checking the regulating pressure, screw the regulator itself down to the desired pressure.